Manufacturing the Best in the Pharma Arena

● Dispensing of materials under an SS reverse laminar flow

● Separate air-handling units for every production department, with classified filtration as per cGMP norms

● Individual compression and coating cabin with separate air-handling units to avoid cross contamination

● Well-equipped Quality Control Laboratory with modular furniture, including HPLC Microbiology & Sterility area under class 10,000

● Separate double-skin AHVs for vial/ampoule washing, sterilization, buffer-zone and airlocks, filling areas conforming to class D, C, and B

● Separate AHU for powder filling areas

● State of art vial/plastic dropper filling/sealing line for untouched operation

● Visual inspection of ampoules with semi and automatic inspection machines

● Water Treatment system with RO (Reverse Osmosis) & EDI (Electron de-Ionization) and SS 316L pipeline in loop form, with a 5-micron filter

and UV lamp for absolute purity of water

● Multicolumn Distilled water plant with storage & Distribution at through SS316L lines in closed loop

● Extensive training and retraining of personnel to ensure they stay current with latest technological developments

● Alternative power generation system for uninterrupted production

● A unidirectional flow of men and materials to promote optimum productivity

● Accessibility of all utilities and maintenance areas from outside, for additional ease of operation

● Ample segregated storage for raw materials and packaging materials, with cold room facilities for raw material, quarantine & furnished goods

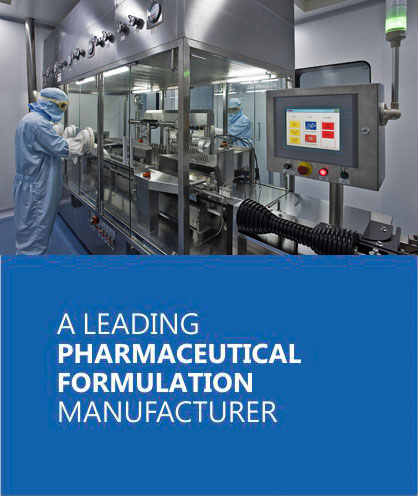

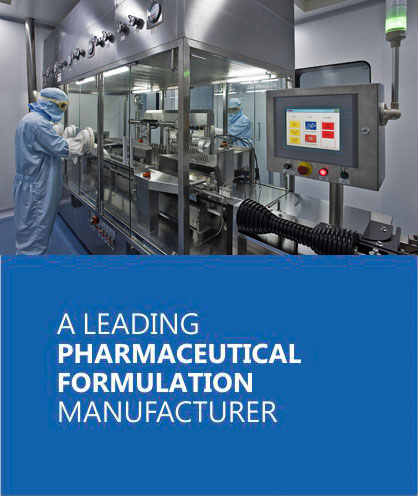

CIRON manufactures a wide range of Pharmaceutical formulations at its independent,

state-of- the-art manufacturing facilities, which also house independent quality control departments and research & development units.

The CIRON Group has two fully automated, state-of- the-art independent production

units. We are also coming up with a third state of the art sterile facility, specifically targeted

for the regulated markets.

At our Tarapur plant, we manufacture small volume parenteral (Vials, Ampoules, and

Lyophilized Vials), Eye/Ear/Nasal Drops, Liquid Orals, and external products.

Our Palghar manufacturing unit includes manufacturing facilities of tablets, capsules, liquids and dry syrups (dry powder) at Palghar.

A competent, experienced and motivated production & quality-control staff manages the CIRON Group. The company is comprised of highly educated professionals in their respective departments, such as Production, R&D, and Marketing.

All products are tested thoroughly at different stages of procurement, production, packing, and distribution to ensure optimum quality. The company has an in-house quality controldepartment that has all the modern testing facilities.

The company, since the time of its inception, has been constantly striving to provide technological superiority, high-quality products at the most competitive prices.

Highest priority is given to the quality-control factor and adequate precautions are taken to ensure that there are no lapses on the production front.

CIRON Plant embraces GMP (Good Manufacturing Practice) Standards, including WHO GMP norms laid down by the World Health Organization and cGMP norms laid down in the "Revised Schedule M" by the Drug Controller (General) India, Ministry of Health, and Government of India.

Moreover, our operations are ISO 9001:2015 certified.